Simple Serial Interface Protocol

I need a simple communication protocol between two devices (a PC and a microcontroller). The PC must send some commands and parameters to the micro. The micro must transmit an array of bytes (data from sensor).The data must be (besides parity checking, I think I need some other data correction method).Is there any standard solution to do this? (I need only an idea, not the complete solution).P.S. Any advice is appreciated. P.P.S Sorry for any grammar mistakes, I hope you understand.Edit 1.

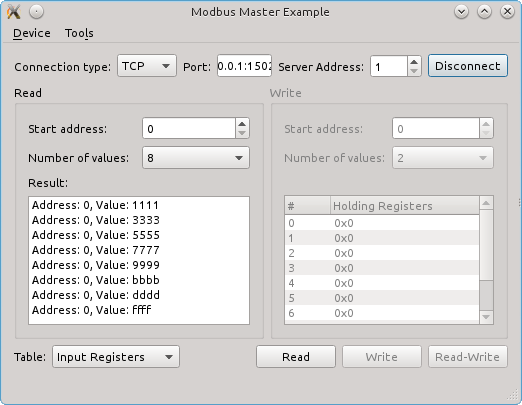

I have not decided whether it will be master/slave protocol or both sides can initiate communication. The PC must know when micro have done a job and can send data.

It can continuously poll the micro if data is ready, or the micro can send data, when a job is done. I don't know which is better and simpler.Edit 2. Hardware and protocol. Since C serial standard used in the PC, I will use.

I will use only RxD, TxD and GND signals. I can't use additional wires because the microcontroller AFAIK doesn't support them.

BTW I'm using the ATmega128 chip.So I will use fixed baud rate, 8 bits of data, 2 stop bits without parity checking (or with?). That's what my question primarily concerned about. Thanks for suggesting, and protocols. I will research on it. I have had good luck with it in the past.

I would for a point to point serial just use the and forget about all of the other control stuff as it would probably be overkill.In addition to using HDLC for the framing of the packet. I format my packet like the following. This is how options are passed using 802.11 U8 cmd;U8 len;u8 payloadlen;The total size of each command packet is len +2You then define commands like #define TRIGGERSENSOR 0x01#define SENSORRESPONSE 0x02The other advantage is that you can add new commands and if you design your parser correctly to ignore undefined commands then you will have some backwards compatibility.So putting it all together the packet would look like the following. // total packet length minus flags len+4U8 sflag; //0x7e start of packet end of packet flag from HDLCU8 cmd; //tells the other side what to do.U8 len; // payload lengthU8 payloadlen; // could be zero lenU16 crc;U8 eflag; //end of frame flagThe system will then monitor the serial stream for the flag 0x7e and when it is there you check the length to see if it is pklen = 4 and pklen=len+4 and that the crc is valid.

Note do not rely on just crc for small packets you will get a lot of false positives also check length. If the length or crc does not match just reset the length and crc and start with decoding the new frame. If it is a match then copy the packet to a new buffer and pass it to your command processing function.

Always reset length and crc when a flag is received.For your command processing function grab the cmd and len and then use a switch to handle each type of command. I also require that a certain events send a response so the system behaves like a remote procedure call that is event driven.So for example the sensor device can have a timer or respond to a command to take a reading. It then would format a packet and send it to the PC and the PC would respond that it received the packet.

If not then the sensor device could resend on a timeout.Also when you are doing a network transfer you should design it as a network stack like the as points don't forget about the. My post with the HDLC is the and the. RS232 protocols are tricky.

The suggestion to use HDLC, is a good one, but its not the entire solution. There are other things you need to decide:. How will the baud rate between the two devices be determined? Predefined, or set explicate?. Will you do flow control in software or hardware or both? Note, if you use hardware flow control then you must make sure, that the cables are built correctly. Speaking of cables, this is a huge pain with RS233.

Depending on the device, you may need to use a straight through cable, or a cross over cable, or a variant. Using a software based flow control mechanism can be effective as it allows the most simple cable to be used - just three wired (TX, RX, and common). Do you pick a 7 or 8 bit word?. HW parity or software error checking.I suggest you go with 8 data bits, no hardware parity, 1 stop bit, and use software based flow control. You should use autobaud if your hardware supports it.

If not, then autobaud is devilishly difficult to do in software. There are some good answers in here, here are some useful pointers:Even if your packets are not time-separated, the sync byte is an essential way of reducing the number of places you need to attempt to construct a packet from. Your devices will often have to deal with a bunch of junk data (i.e the end of a packet in flight when they turned on, or result of a hardware collision). Without a sync byte you will have to try to make a packet out of every byte you receive.

The sync byte means that only 1/255 bytes of random noise could be the first byte of your packet. Also FANTASTIC when you want to snoop on your protocol.Having an address on your packets or even just a bit saying master / slave or pc / device is useful when you look at the packets via a of some type or another.

Serial Communication Protocol

You might do this by having a different sync byte for the PC than the DEVICE. Also, this will mean a device will not respond to its own echo.You might want to look into error correction (such as ). You package 8 bit of data into a 12 bit protected byte.

Any one of those 12 bits can be flipped en-route and the original 8 bits retrieved. Useful for data storage (used on CDs) or where the device can't re-send easily (satellite links, one-way rf).Packet numbers make life easier. A packet sent carries a number, responses carry the same number an a flag saying 'response'. This means that packets that never arrived (sync corrupted say) are easily detected by the sender and in full-duplex mode with a slow link, two commands can be sent before the first response is received. This also makes protocol analysis easier (A third party can understand which packets were received with no knowledge of the underlying protocol)Having a single master is an awesome simplification.

Simple Serial Interface Protocol Software

That said, in a full-duplex environment it does not matter much at all. Suffice to say you should always do it unless you are trying to save power or you are doing something event driven at the device end (input state changed, sample ready). I read this question a few months back, having exactly the same issue, and didn't really find anything efficient enough for a tiny 8-bit micro with tiny amounts of RAM. So inspired by CAN and LIN I built something to do the job. I called it MIN (Microcontroller Interconnect Network) and I've uploaded it to GitHub here:There are two implementations there: one in embedded C, one in Python for a PC.

Plus a little 'hello world' test program where the PC sends commands and the firmware lights an LED. I blogged about getting this up and running on an Arduino board here:MIN is pretty simple. I fixed the layer 0 representation (8 data bits, 1 stop bit, no parity) but left the baud rate open. Each frame starts with three 0xAA bytes which in binary is, a nice pulsetrain to do autobaud rate detection if one end wants to dynamically adapt to the other.

Frames are 0-15 bytes of payload, with a 16-bit Fletcher's checksum as well as a control byte and an 8-bit identifier (to tell the application what the payload data contains).The protocol uses character stuffing so that 0xAA 0xAA 0xAA always indicates start-of-frame. This means that if a device comes out of reset it always syncs with the start of the next frame (a design goal for MIN was never to pass up an incomplete or incorrect frame). This also means there's no need to have specific inter-byte and inter-frame timing constraints.

Full details of the protocol are in the GitHub repo wiki.There's room for future improvements with MIN. I've left some hooks in there for block message passing (4 bits of the control byte are reserved) and for higher-level negotiation of capabilities (identifier 0xFF is reserved) so there's plenty of scope for adding support for commonly required functionality. Here's an alternative protocol: u8 Sync // A constant value which always marks the start of a packetu16 Length // Number of bytes in payloadu8 DataLength // The payloadu16 Crc // CRCUse RS232/UART, as the PC (serial port) and the processor (UART) can already handle that with minimum fuss (just need a chip or similar to do the level shifting).And using RS232/UART, you don't have to worry about master/slave if it's not relevant.

Flow control is available if necessary.Suggested PC software: either write your own, or for simple monitoring and control (evaluation version is free).For greater error checking, simplest is parity checking, or if you need something more powerful, maybe.In any case, whatever you do: keep it simple!EDIT: Using RS232 with a PC is even easier than it used to be, as you can now get USB to RS232/TTL converters. One end goes into your PC's USB socket, and appears as a normal serial port; the other comes out to 5 V or 3.3 V signals that can be connected directly to your processor, with no level-shifting required.We've used from FDTI Chip, which works perfectly for this kind of application. I think I need to guarantee that Sync number will not occur in Length, Data and CRC.

Also I need to control that data is delivered (by transmitting some response to data). So I have to worry about master/slave.

By flow control you mean hardware flow control? I think I will not use it. I will write PC software myself. I've chosen Linux operating system for the PC, so Docklight is not relevant. If I will use CRC, why I have to use parity checking?

I haven't heard about convolutional coding, so I will check it out. Thank you for your comment.–May 4 '09 at 21:13.

My only suggestion is if you need noise-resistant you might want to use full-duplex RS-422/485. You can use an IC similar to on the AVR side, then an RS-232-RS-422 converter on the PC side like.

If you can find or make a shielded cable (two twisted shielded pairs) then you'll have even more protection. And all of this is invisible to the micro and PC - no software changes.Whatever you do make sure that you are using a full-duplex system and make sure the read/write enable lines are asserted on the IC. Regarding parity checks (as it's come up a few times here):They're mostly useless. If you're concerned that a single bit may be changed in error, then it's highly likely that a second bit may also change and you'll get a false positive from the parity check.Use something lightweight like CRC16 with a lookup table - it can be calculated as each byte is received and is basically just an XOR. Steve Melnikoff's suggestion is great for small micros.I would also suggest transmitting human readable data, rather than raw binary (if performance is not your first priority). It will make debugging and log files much more pleasant.

You do not specify exactly how the microcontroller behaves, but will everything transmitted from the micro be a direct response to a command from the PC? If do then it seems like you can use a master/slave protocol of some kind (this will typically be the simplest solution). If both sides can initiate communication, you need a more general data link layer protocol. Is a classic protocol for this.

Although the full protocol probably is a overkill for your needs, you could for instance at least use the same frame format. You might also have a look at to see if there are something useful parts.

1Simple Object Access Protocol OverviewThis chapter provides an overview of the Simple Object Access Protocol (SOAP), and includes a description of the architecture of the Oracle SOAP implementation.This chapter covers the following topics:.What Is the Simple Object Access Protocol?The Simple Object Access Protocol (SOAP) is a lightweight, XML-based protocol for exchanging information in a decentralized, distributed environment. See Also:for information on Simple Object Access Protocol (SOAP) 1.1 specificationHow Does SOAP Work?The SOAP specification describes a standard, XML-based way to encode requests and responses, including:.

Requests to invoke a method on a service, including in parameters. Responses from a service method, including return value and out parameters. Errors from a serviceSOAP describes the structure and data types of message payloads by using the emerging W3C XML Schema standard issued by the World Wide Web Consortium (W3C). SOAP is a transport-agnostic messaging system; SOAP requests and responses travel using HTTP, HTTPS, or some other transport mechanism.illustrates the components in the SOAP architecture.

In general, a SOAP service remote procedure call (RPC) request/response sequence includes the following steps:. A SOAP client formulates a request for a service. This involves creating a conforming XML document, either explicitly or using Oracle SOAP client API. A SOAP client sends the XML document to a SOAP server. This SOAP request is posted using HTTP or HTTPS to a SOAP Request Handler running as a servlet on a Web server. Shows the body of a SOAP message, an XML document, that represents a SOAP request for a service that provides an address from an address book.

The Web server receives the SOAP message, an XML document, using the SOAP Request Handler Servlet. The server then dispatches the message as a service invocation to an appropriate server-side application providing the requested service.

A response from the service is returned to the SOAP Request Handler Servlet and then to the caller using the standard SOAP XML payload format. Contains the body of a response to the request made in.